Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

✦ From Lost-Wax Art to High-Tech Manufacturing

Investment casting, also known as the lost-wax process, is one of the oldest known metal-forming techniques—yet remains a cornerstone of modern high-precision manufacturing. With its ability to produce complex, near-net-shape components, it has evolved from a handcrafted art into a high-tech solution for industries like aerospace, automotive, and medical equipment.

✦ A 4,000-Year Legacy

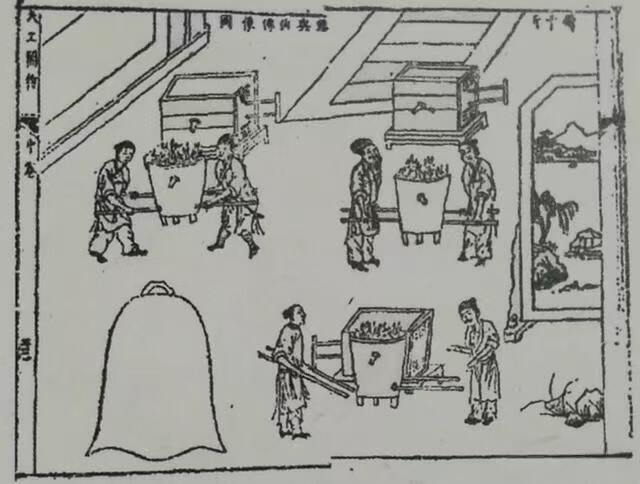

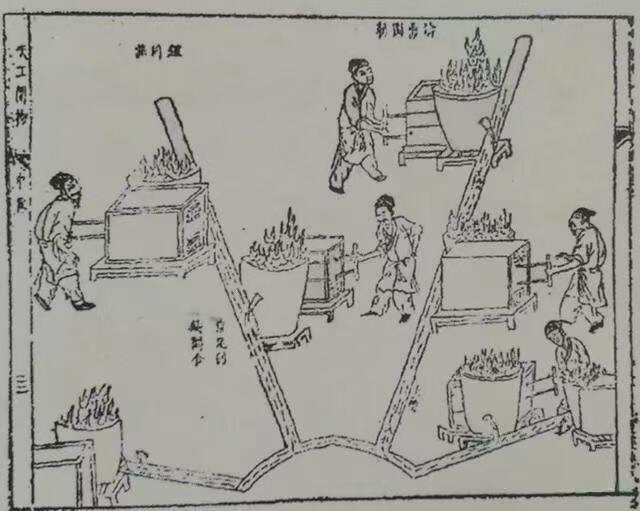

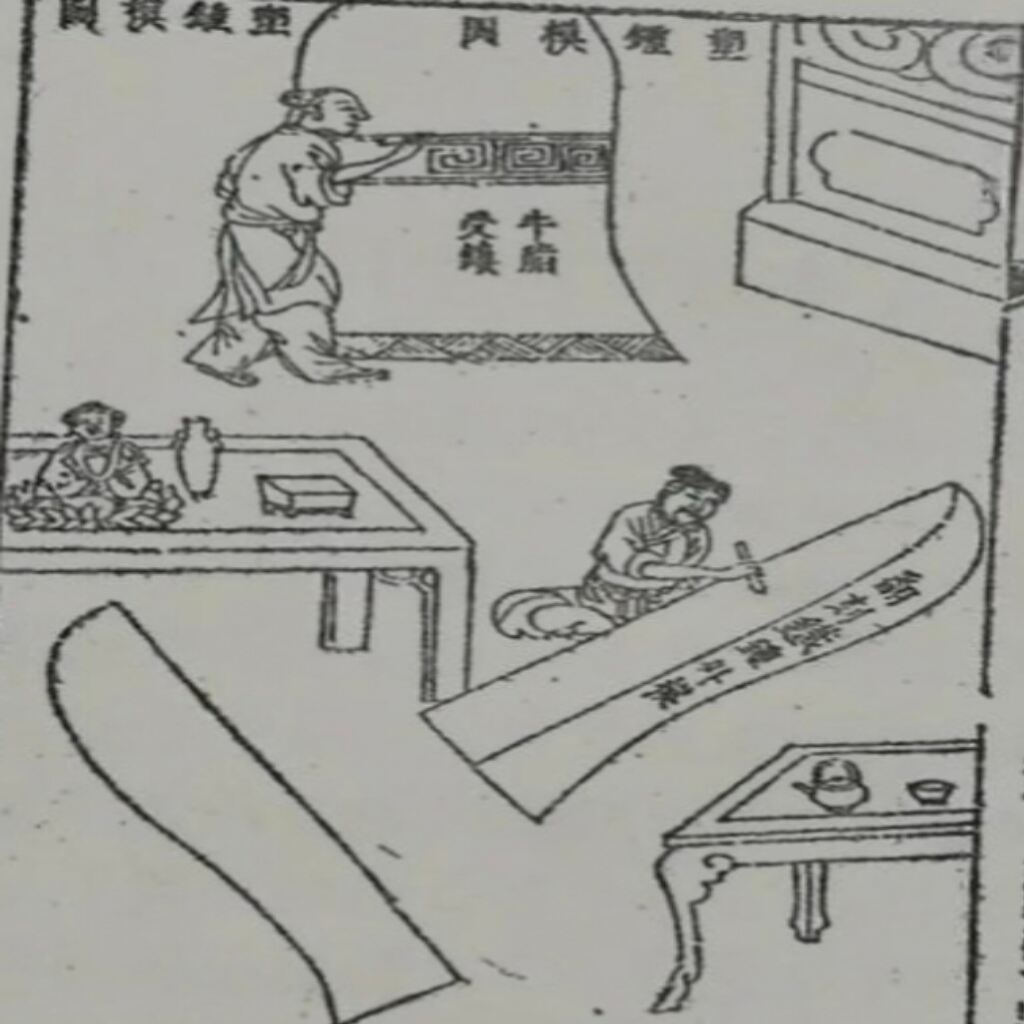

The roots of investment casting date back over four millennia to ancient Mesopotamia. Early artisans used beeswax models and clay molds to cast copper, bronze, and gold objects. Civilizations such as ancient Egypt, the Han Dynasty in China, and the Benin Kingdom in Nigeria perfected this technique for producing intricate idols, jewelry, and ceremonial tools.

In Benin, traditional brass casters still use a similar process today: shaping beeswax patterns over a clay core, applying layers of clay to form a mold, then melting out the wax and pouring in molten metal. Each piece is unique and hand-crafted, preserving a legacy of craftsmanship that continues to inspire.

✦ Rediscovered by Industry

Though used for centuries in art and sculpture, investment casting was largely overlooked by modern industry until the late 19th century. In 1897, dentist Dr. D. Philbrook documented its use in making dental crowns. A decade later, Dr. William H. Taggart revolutionized the process by developing improved wax compounds, investment materials, and a pressure casting machine, bringing investment casting into the industrial era.

During World War II, demand for precision parts surged. Investment casting became crucial for producing components that machining couldn't deliver, particularly using high-performance alloys. It offered speed, accuracy, and material flexibility.

✦ Modern Applications & Advancements

Today, investment casting is powered by 3D printing, CAD/CAM design, vacuum and countergravity casting, and robotic automation. These advancements allow for tighter tolerances, faster production, and higher repeatability.

Industries now rely on investment casting for:

- Jet engine and turbine components

- Surgical implants and orthopedic tools

- Automotive turbochargers and transmission parts

- High-performance pumps, valves, and fittings

✦ From Craftsmanship to Cutting-Edge

What began as an ancient craft is now a critical technology in the world's most advanced industries. Investment casting bridges the gap between design complexity and production efficiency, offering unmatched versatility and precision.

As global demand for lightweight, durable, and complex parts continues to rise, investment casting will remain an essential process for shaping the future of manufacturing.

Hot News

Hot News