Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

Sand Casting

1.Definition

Sand casting, also known as sand mold casting, is a widely used metal casting method that utilizes sand as the primary mold material. Over 80% of cast metal parts worldwide are produced using this process.

This technique involves compacting sand mixed with a binder—usually clay—and water to form a mold cavity around a pattern. Once the mold is formed, molten metal is poured into the cavity to create the final part.

Sand casting is known for its low cost, high adaptability, and ability to produce large or complex components. It is suitable for casting iron, steel, and non-ferrous alloys, and is widely applied in industries such as automotive, machinery, and construction.

2.Process

Mold Making

Sand is packed around a pattern to create the mold cavity, with cores added for internal shapes. Lubricants are applied to help remove the casting and improve metal flow and surface finish.

Pouring

After positioning the cores and securely closing the mold, molten metal is poured quickly to fill the entire cavity and channels before solidification begins.

Cooling

The molten metal cools and solidifies inside the mold, forming the final casting shape. Cooling time depends on part thickness and metal temperature, and proper cooling prevents defects such as shrinkage and cracks.

Removal

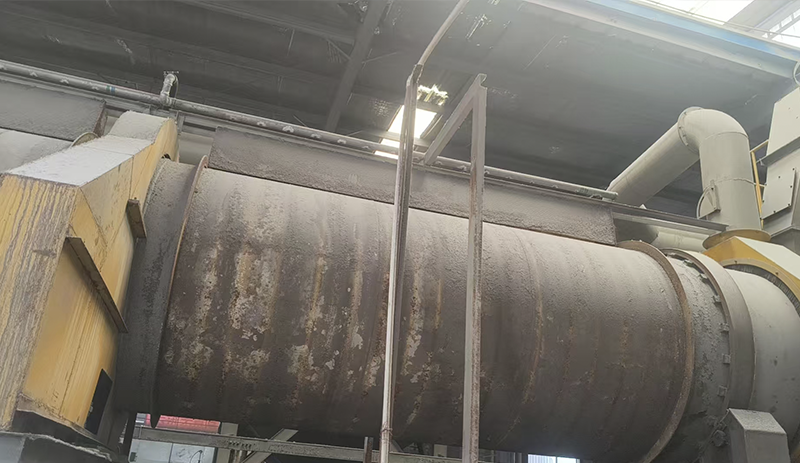

Once cooled, the sand mold is broken apart to release the casting, which is then cleaned of residual sand and oxides, often using abrasive blasting.

Trimming

Excess metal from pouring channels solidifies on the casting and must be trimmed off by cutting or sawing. The trimmed material is either discarded or recycled.

3.Application

Today, sand casting is widely used across various industries, including automotive, railway, construction machinery, mining equipment, logistics, and agriculture. This casting method is valued for its strength, durability, and precision, as well as its excellent design flexibility. Sand casting meets the demanding requirements of engine components, heavy machinery parts, wear-resistant mining equipment, and critical load-bearing parts in logistics and agricultural machinery. It is ideal for both standard production and customized solutions.

4.Advantages

Sand casting offers a range of benefits that make it a popular choice for many manufacturing applications. These advantages include:

- Cost-Effective: Sand casting features low tooling and mold production costs, making it ideal for small to medium production runs, prototypes, and custom parts. The simplicity of sand molds and patterns significantly reduces initial investment compared to other casting methods.

- Wide Material Compatibility: This method supports nearly all ferrous and non-ferrous alloys, including iron, steel, aluminum, brass, and more, offering great flexibility in material selection.

- Versatile Size and Shape: Sand casting can produce parts ranging from small components to extremely large castings exceeding 200 tons. The use of cores enables the creation of complex internal geometries and hollow sections in a single casting.

- Faster Lead Times: Compared to some other casting methods, such as investment casting, sand casting often achieves shorter cycle times, which helps meet tight production schedules.

- Flexible Production Volume: Whether for one-off prototypes or large-scale manufacturing, sand casting adapts well to different quantities without significantly raising costs.

5.Q&A

Can sand-cast parts be machined?

Yes, sand-cast parts often require machining for critical dimensions or surface finishes.

Is sand recyclable?

Yes, sand can be reused multiple times after proper conditioning, reducing waste and cost.

What industries commonly use sand casting?

Automotive, aerospace, heavy machinery, agriculture, and construction industries frequently use sand casting.

What are the environmental concerns of sand casting?

Handling and disposal of sand and foundry dust can pose environmental challenges; modern foundries apply controls to mitigate these.

How does sand casting compare to investment casting?

Sand casting is cheaper and better suited for large parts, but offers lower precision and surface finish than investment casting.

How can I reduce the cost of sand casting?

Design for manufacturability by minimizing cores, using uniform wall thickness, standardizing parts, and reducing machining needs can lower costs.