Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

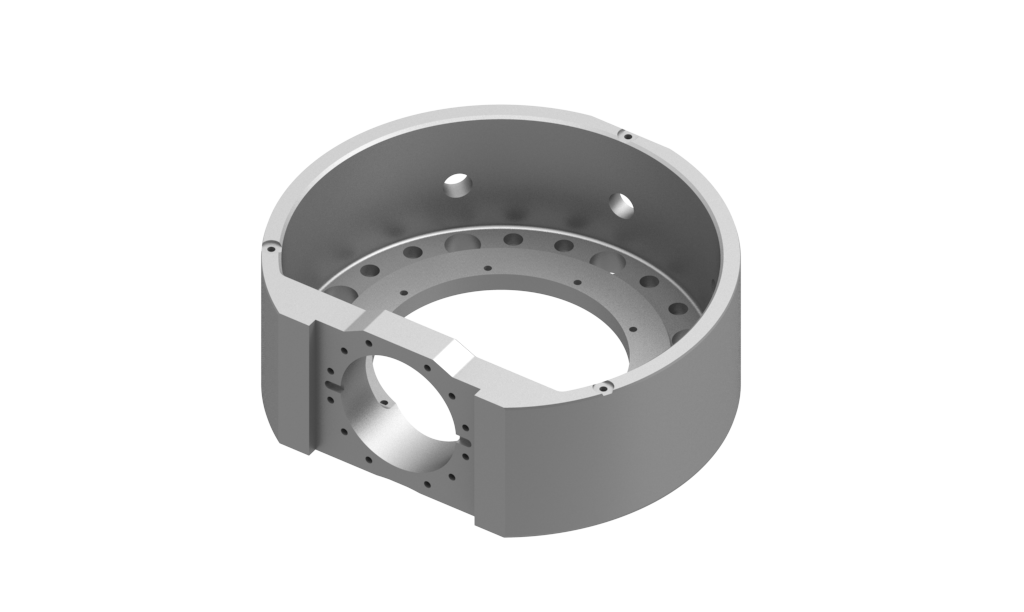

Professional quality assurance solutions are integral to our manufacturing philosophy at Ningbo Xingxin Industrial Co., Ltd. We understand that in the highly competitive global market, ensuring the quality of our products is not only a requirement but also a key differentiator. Our quality assurance solutions cover the entire manufacturing process, from raw material sourcing to final product delivery. We have a strict supplier evaluation and selection system to ensure that only high - quality raw materials enter our production lines. In - process quality control is carried out at multiple stages, with our technicians using advanced inspection tools and techniques to monitor critical manufacturing parameters. For example, in the casting process, we continuously monitor metal pouring temperatures, mold filling rates, and solidification times to prevent casting defects. Our final product inspection is comprehensive. We use a combination of non - destructive testing methods, such as ultrasonic testing and radiographic testing, to detect internal flaws, and destructive testing, including tensile testing and hardness testing, to evaluate mechanical properties. In addition, we have a quality management system that is regularly audited and updated to meet international standards. Our professional quality assurance solutions not only ensure that our products meet or exceed the expectations of our clients but also contribute to building long - term trust and partnerships in the global market.