Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

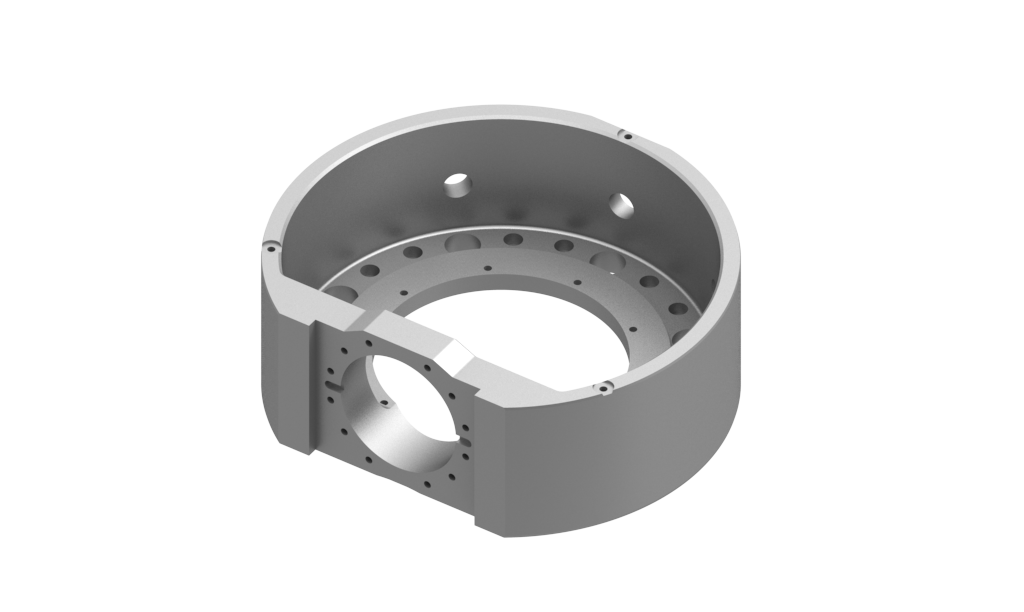

At Ningbo Xingxin Industrial Co., Ltd., we understand the importance of cost - effectiveness in the manufacturing industry. Our low cost sand casting components offer a perfect balance between affordability and quality, making them an ideal choice for clients looking to optimize their production costs without compromising on performance. We achieve cost savings through efficient production processes, bulk purchasing of raw materials, and continuous improvement in our manufacturing techniques. By streamlining our operations, we can reduce production time and waste, passing on the cost benefits to our clients. However, our commitment to quality remains unwavering. We use quality - assured raw materials and maintain strict quality control throughout the sand casting process. Our low cost sand casting components are suitable for a variety of applications, from general industrial use to consumer goods production. Whether it's a small - scale project or a large - volume order, we can provide cost - effective sand - cast components that meet the required specifications. With our low cost yet high - quality offerings, we help our clients enhance their competitiveness in the global market.