Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

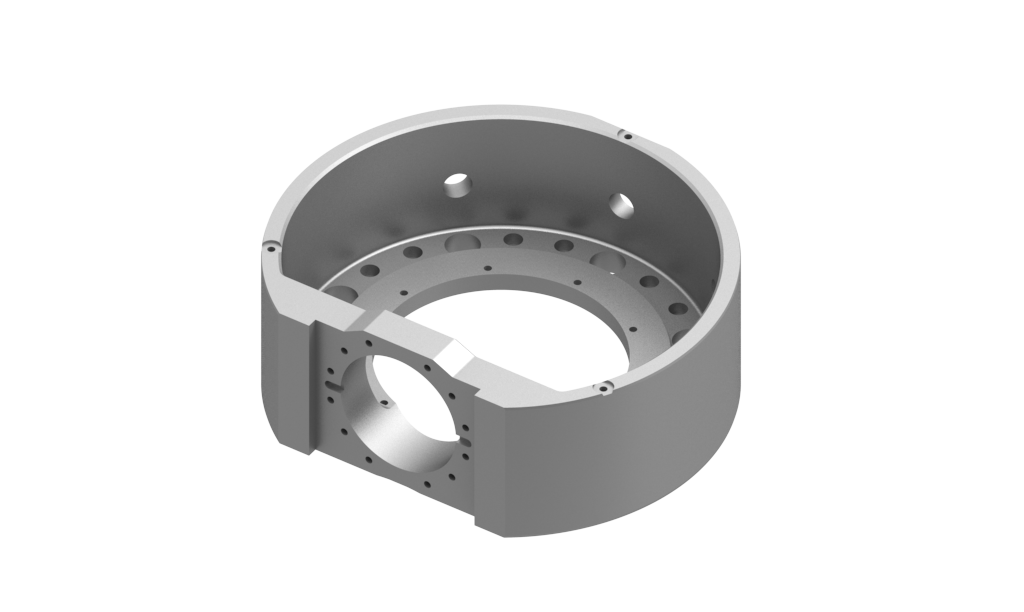

Precision sand casting components are our specialty at Ningbo Xingxin Industrial Co., Ltd. We have mastered the art of producing sand - cast parts with high precision, meeting the stringent requirements of various industries. Our precision sand casting process begins with meticulous mold preparation. We use advanced 3D modeling and simulation techniques to optimize the mold design, ensuring accurate part formation. High - quality sands and binders are used to create molds with excellent dimensional stability. During the casting process, precise control of metal pouring parameters, such as temperature and speed, is maintained to minimize casting defects. After casting, our precision machining operations further enhance the accuracy of the components. We use high - precision CNC machines to achieve tight tolerances and fine surface finishes. In industries such as aerospace, where even the slightest deviation can have significant consequences, and the medical device industry, where precision is essential for functionality and safety, our precision sand casting components have been widely recognized. With a comprehensive quality control system that includes in - process inspection and final product testing, we ensure that every precision sand casting component we produce meets the highest international standards of quality and precision.