Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

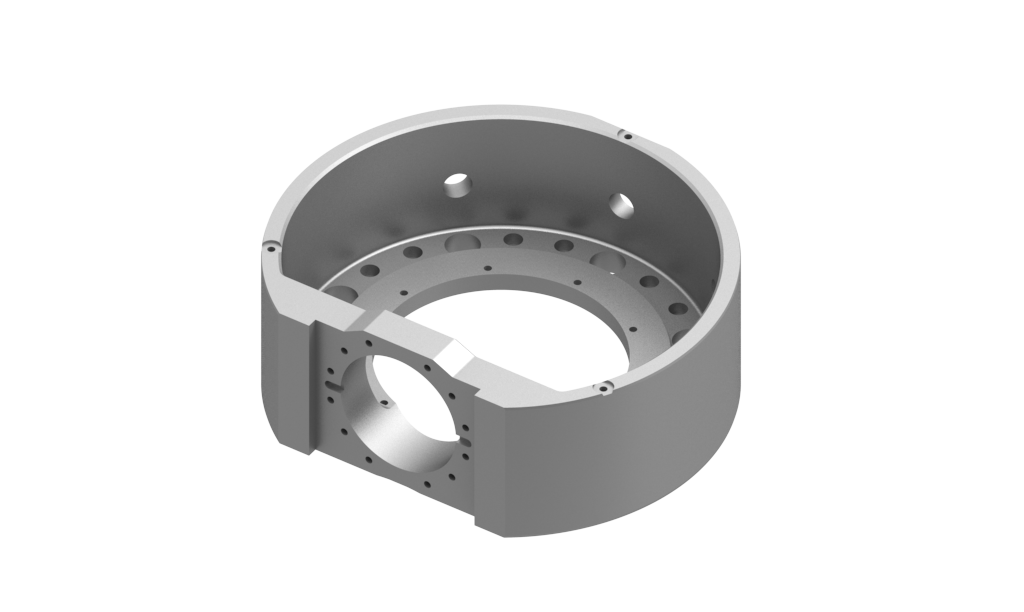

Sand casting is a versatile and widely used manufacturing process, and our sand casting components parts at Ningbo Xingxin Industrial Co., Ltd. are known for their quality and reliability. We produce a vast range of sand - cast components, each designed to meet the specific needs of different industries. Our sand casting process starts with creating precise molds using high - quality sands and advanced molding techniques. The metal is then melted and poured into these molds with careful control of temperature and pouring speed to ensure a defect - free casting. After solidification, the parts undergo a series of post - processing operations, including cleaning, machining, and surface treatment, to achieve the desired dimensions, surface finish, and mechanical properties. Whether it's large - scale structural components for the construction industry, functional parts for agricultural machinery, or engine components for the automotive sector, our sand casting components parts are manufactured to the highest standards. We adhere to international quality norms and use strict quality control measures at every stage of production, ensuring that our sand - cast components are ready to perform reliably in their intended applications.