Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

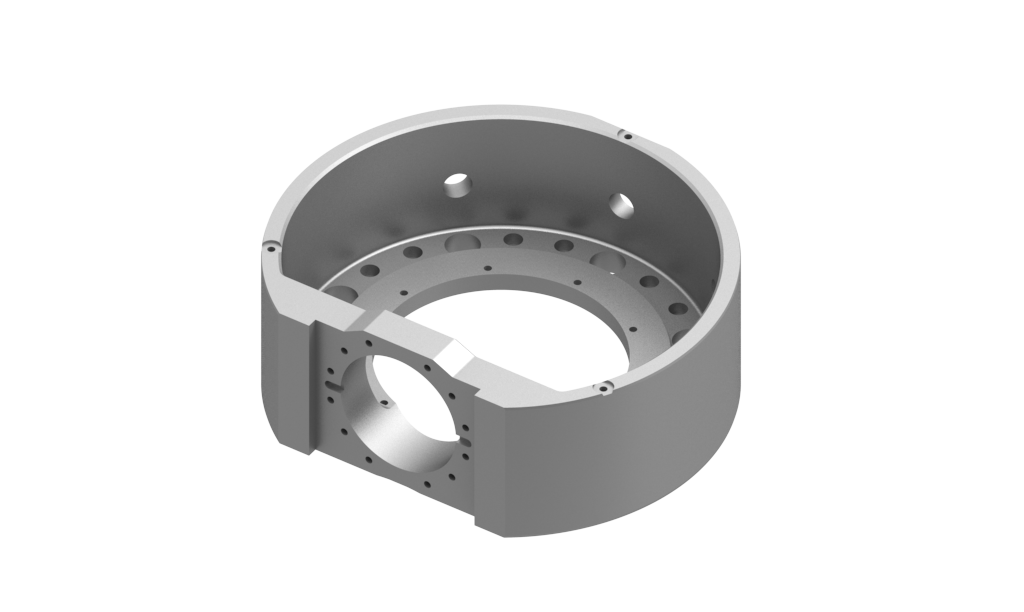

Aluminum sand casting components have become indispensable in numerous industries due to their unique properties, and Ningbo Xingxin Industrial Co., Ltd. stands as a premier producer in this domain. Our expertise in aluminum sand casting is built upon a foundation of advanced techniques and stringent quality control. The process begins with the selection of high - grade aluminum alloys, carefully chosen based on the specific requirements of the components, such as strength, corrosion resistance, and thermal conductivity. Our state - of - the - art molding facilities utilize high - quality sands and binders to create precise molds. These molds are designed to ensure the accurate formation of aluminum components, whether they are large structural parts for the construction industry or intricate components for the automotive sector. During the casting process, we employ advanced melting furnaces with precise temperature control systems. This allows us to pour the molten aluminum at the optimal temperature, minimizing the risk of defects such as porosity and shrinkage. After casting, our post - processing operations, including machining, surface finishing, and heat treatment if required, are carried out with meticulous attention to detail. We can produce a wide range of aluminum sand casting components, from simple brackets and housings to complex engine parts. With a focus on meeting international quality standards and understanding the diverse needs of global clients, our aluminum sand casting components are trusted for their reliability, performance, and cost - effectiveness.