Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

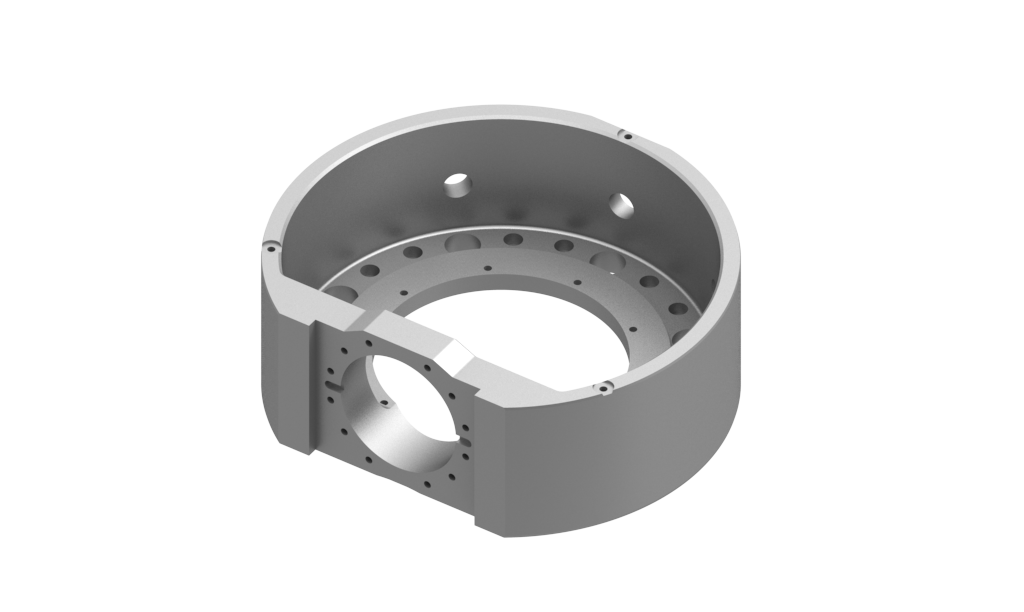

Industrial sand casting components are the backbone of many manufacturing processes, and at Ningbo Xingxin Industrial Co., Ltd., we are experts in their production. Our industrial sand casting components are designed and manufactured to withstand the harsh conditions of various industrial applications. We use a variety of metals, including iron, steel, and aluminum alloys, to produce components that offer different mechanical properties and performance characteristics. Our sand casting processes are optimized for industrial use, with a focus on high - volume production, cost - effectiveness, and quality consistency. In the manufacturing of heavy - machinery, our industrial sand casting components form the structural and functional parts that enable the equipment to operate efficiently. For the energy industry, our components are used in power generation and transmission systems. We adhere to strict industrial standards and regulations during production, ensuring that our industrial sand casting components are safe, reliable, and compliant. With a commitment to innovation and continuous improvement, we strive to provide industrial sand casting components that meet the evolving needs of the global industrial market.