Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

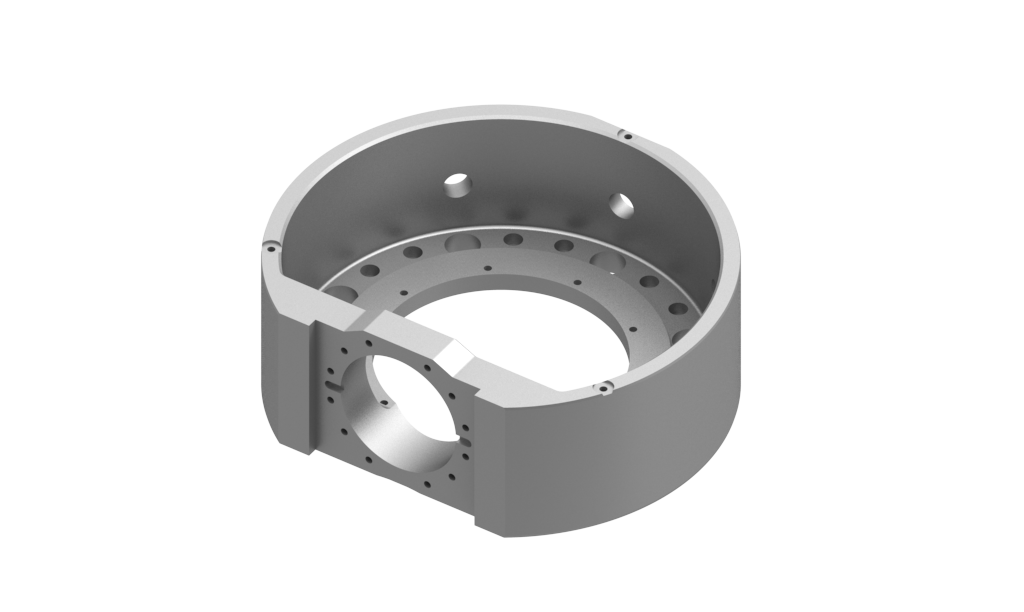

As an OEM sand casting manufacturer, Ningbo Xingxin Industrial Co., Ltd. is dedicated to providing customized sand casting solutions to clients around the world. Our OEM services cover the entire product lifecycle, from concept design to mass production. Our experienced engineering team collaborates closely with clients, using advanced CAD/CAM software to translate their ideas into detailed design drawings. We take into account factors such as part functionality, manufacturability, and cost - effectiveness during the design process. Once the design is finalized, our state - of - the - art sand casting facilities, equipped with automated molding machines and efficient melting systems, come into operation. We can produce sand - cast parts in a wide range of materials, including aluminum, iron, and steel alloys. Our quality control system ensures that every OEM sand - cast part meets the client's specifications and international quality standards. With our global export capabilities, we can deliver these customized parts to clients anywhere in the world, providing a seamless OEM sand casting manufacturing experience that meets the highest standards of quality, flexibility, and reliability.