Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

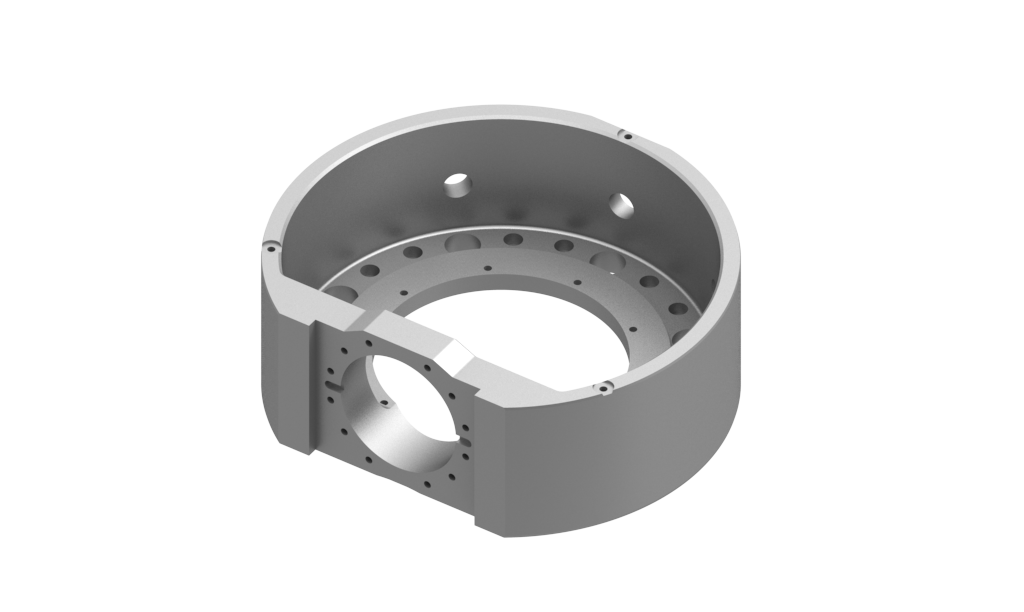

The combination of sand casting and machining at Ningbo Xingxin Industrial Co., Ltd. results in high - quality machined sand casting components that meet the most demanding specifications. Sand casting provides the basic shape and structure of the part, while machining refines the dimensions, surface finish, and functionality. After the sand casting process, our advanced CNC machining centers take over. These machines can perform operations such as milling, turning, drilling, and grinding with high precision. We use computer - controlled programs to ensure that the machining operations are carried out accurately, achieving the required tolerances and surface finishes. For components that require complex geometries or tight dimensional control, our machining capabilities enhance the performance and quality of the sand - cast parts. In industries such as aerospace, where parts need to be lightweight yet strong, and the medical device industry, where precision and biocompatibility are crucial, our machined sand casting components play a vital role. We subject these components to strict quality control, including dimensional inspection, surface roughness measurement, and mechanical property testing, ensuring that they meet the highest international standards and are ready for use in high - end applications.