Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

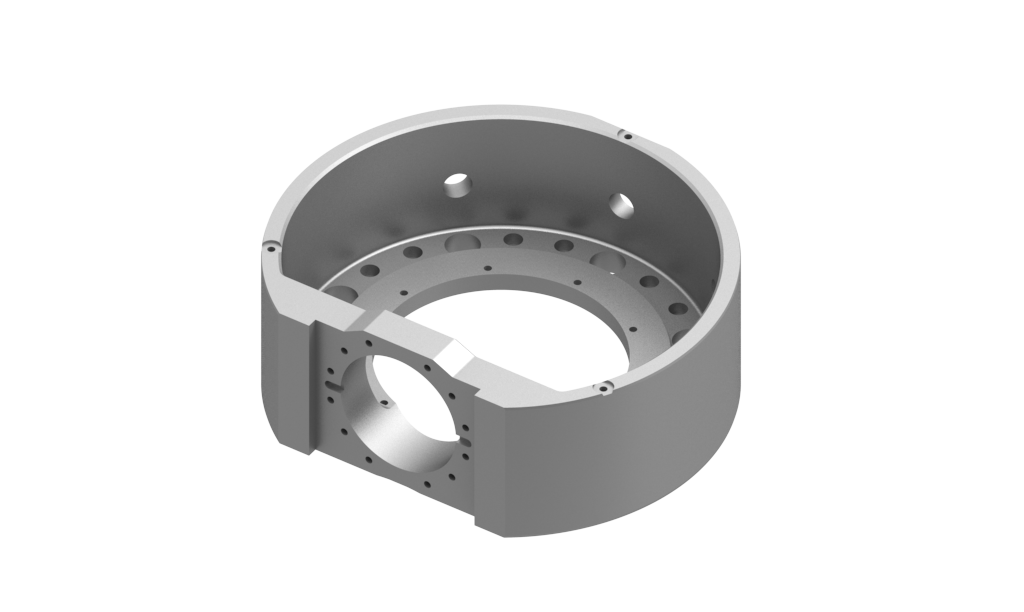

Sand casting components are at the core of our manufacturing capabilities at Ningbo Xingxin Industrial Co., Ltd. We offer a comprehensive range of sand - cast components that are designed, manufactured, and tested to the highest standards, catering to a wide spectrum of industries. Our sand casting process is highly flexible, allowing us to produce components with different levels of complexity and precision. We start by understanding the specific needs of our clients, whether it's for a single - piece prototype or large - volume production runs. Our experienced engineers use advanced simulation software to optimize the casting process, predicting and preventing potential issues such as casting defects and dimensional inaccuracies. In terms of materials, we have extensive experience working with various metals and alloys, ensuring that the components can withstand the demanding conditions of their intended applications. From the initial mold making, where we use high - quality sands and binders for accurate part formation, to the final finishing operations, such as machining, surface coating, and assembly, every step is carefully executed. With a global perspective and a commitment to customer satisfaction, our sand casting components are trusted by clients around the world for their quality, reliability, and cost - effectiveness, enabling us to be a leading provider in the international market for sand - cast components.