Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

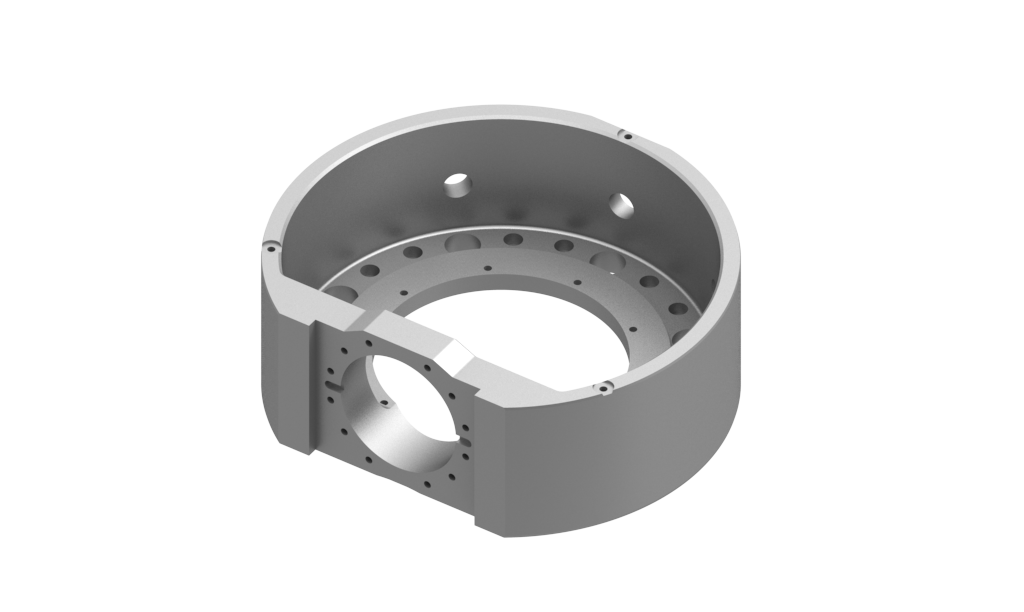

The components of sand casting produced by Ningbo Xingxin Industrial Co., Ltd. are the result of a harmonious blend of traditional craftsmanship and modern manufacturing technologies. Sand casting is a versatile process, and we have mastered the production of a vast array of components to meet the diverse needs of different industries. Our production capabilities cover a wide range of sizes, shapes, and materials. For small - scale components with intricate details, we use precision molding techniques and fine - grained sands to achieve accurate replication. In contrast, for large - scale structural components, we have the expertise and equipment to handle high - volume production while maintaining quality. The materials we work with include ferrous and non - ferrous metals, such as cast iron, steel, aluminum, and copper alloys. Each stage of the sand casting process, from mold preparation to metal pouring and post - processing, is carefully monitored. Our quality control team uses advanced inspection tools, including coordinate measuring machines and non - destructive testing equipment, to ensure that the components meet or exceed the specified requirements. Whether it's a component for construction machinery, agricultural equipment, or industrial automation systems, our components of sand casting are known for their strength, durability, and dimensional accuracy, making them a reliable choice for clients worldwide.