Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

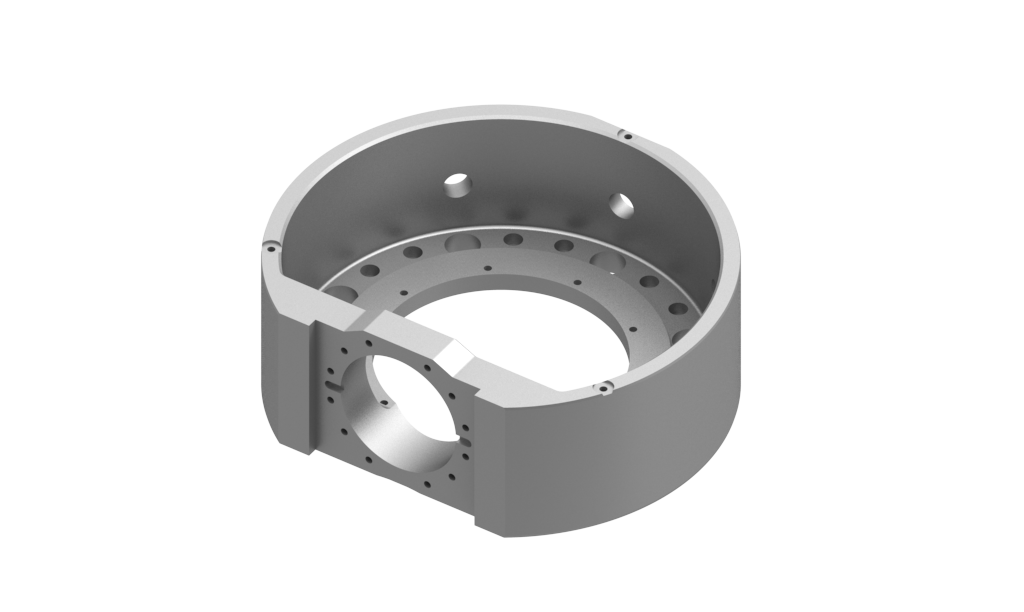

Ningbo Xingxin Industrial Co., Ltd. stands as a reliable industrial sand casting supplier, catering to the diverse needs of the industrial sector. Our extensive experience in sand casting, combined with our advanced production facilities, allows us to provide high - quality sand - cast parts for a wide range of industrial applications. In the heavy - machinery industry, our sand - cast components form the structural and functional elements of equipment that operate in harsh environments. For power generation plants, our parts contribute to the efficient operation of turbines and other critical systems. We understand that industrial applications demand parts with high strength, durability, and reliability. That's why we use premium raw materials and strict quality control measures throughout the sand casting process. Our production capacity enables us to handle both small - batch and large - volume orders, ensuring that we can meet the varying demands of our industrial clients. With a focus on continuous improvement and innovation, we strive to be the go - to industrial sand casting supplier, offering products and services that enhance the performance and competitiveness of our clients' businesses in the global industrial market.