Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

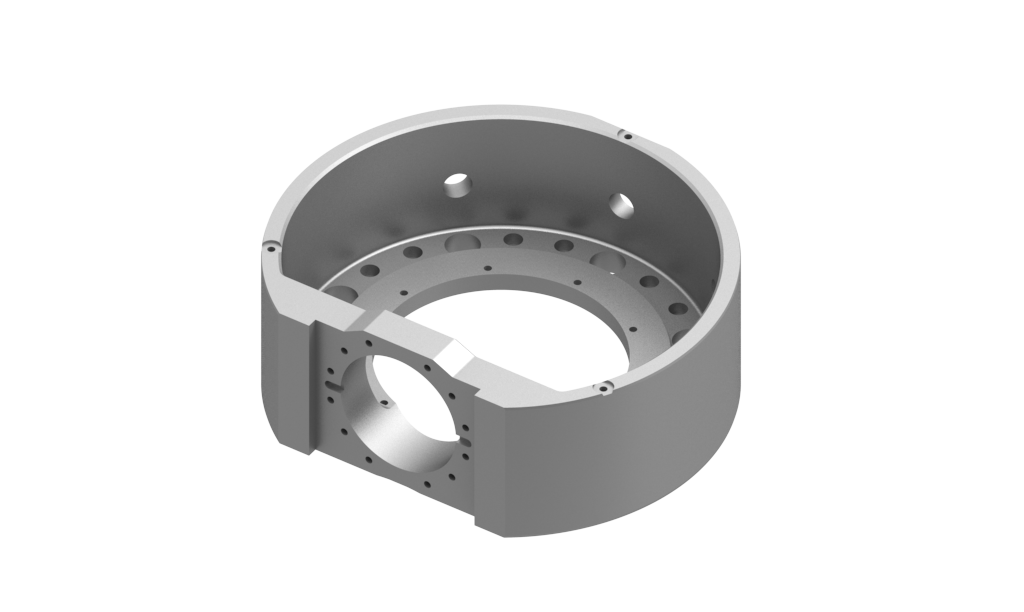

Engine sand casting is a specialized and critical process, and at Ningbo Xingxin Industrial Co., Ltd., we have perfected the art of creating high - performance engine components through sand casting. Engines are the heart of vehicles and many industrial machines, and the quality of their components directly impacts performance, durability, and efficiency. Our engine sand casting process starts with in - depth engineering and design. We work closely with clients, leveraging our advanced CAD/CAM software to develop detailed designs that optimize the functionality and manufacturability of engine parts. Using high - quality sands and advanced molding techniques, we create molds that can accurately replicate the complex geometries of engine components, such as cylinder heads, engine blocks, and intake manifolds. The melting and pouring of metals are carefully controlled. We use high - purity metals and alloys, and our melting furnaces are equipped with precise temperature and composition monitoring systems. This ensures that the molten metal has the right properties to meet the high - stress and high - temperature demands of engine operations. After casting, each engine part undergoes a series of rigorous quality checks, including non - destructive testing to detect internal flaws and dimensional inspection to ensure precise fitment. With our commitment to excellence and continuous improvement in engine sand casting, we provide components that enhance the performance and reliability of engines across various industries, from automotive to power generation.