Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

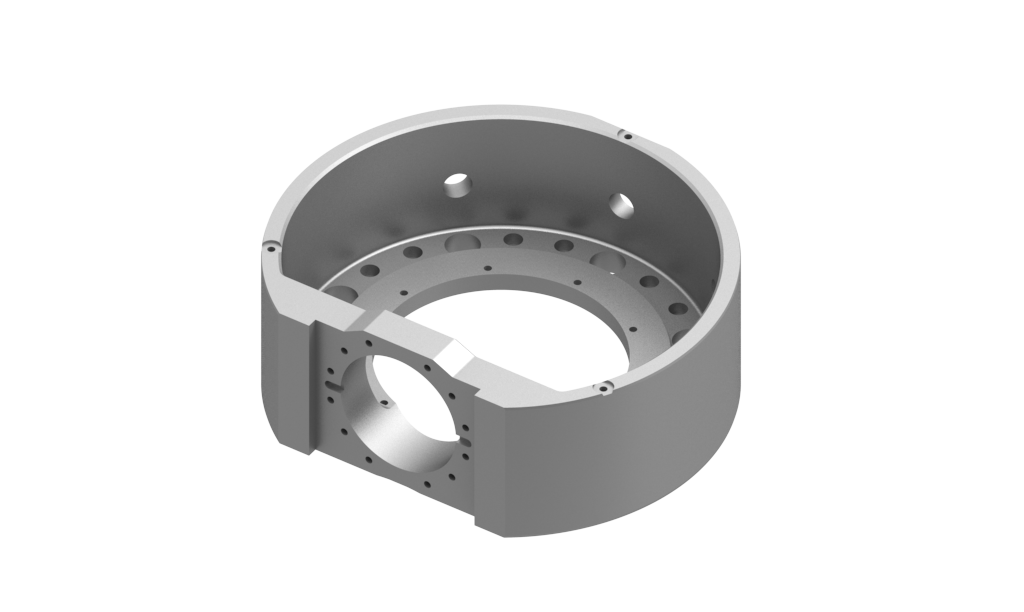

Automotive sand casting components play a crucial role in the automotive manufacturing process, and at Ningbo Xingxin Industrial Co., Ltd., we have extensive experience in producing high - quality components for this industry. Our automotive sand casting components are designed to meet the specific requirements of automotive manufacturers, combining strength, durability, and cost - effectiveness. We use advanced sand casting techniques, such as green sand casting and resin - bonded sand casting, depending on the part's requirements. For engine blocks, cylinder heads, and other large - scale automotive components, sand casting offers an efficient and cost - effective production method. We ensure that the sand - cast automotive components we produce have excellent dimensional accuracy and surface finish, reducing the need for extensive post - machining. Each automotive sand casting component undergoes rigorous quality control, including non - destructive testing for internal defects and destructive testing for mechanical properties. We work closely with automotive clients, providing them with components that are compliant with international automotive standards and ready to be integrated into their production lines. With our focus on quality and customer satisfaction, we are a reliable partner for automotive sand casting components in the global market.