Contact Info

Wangjiaao, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang, P.R. China.

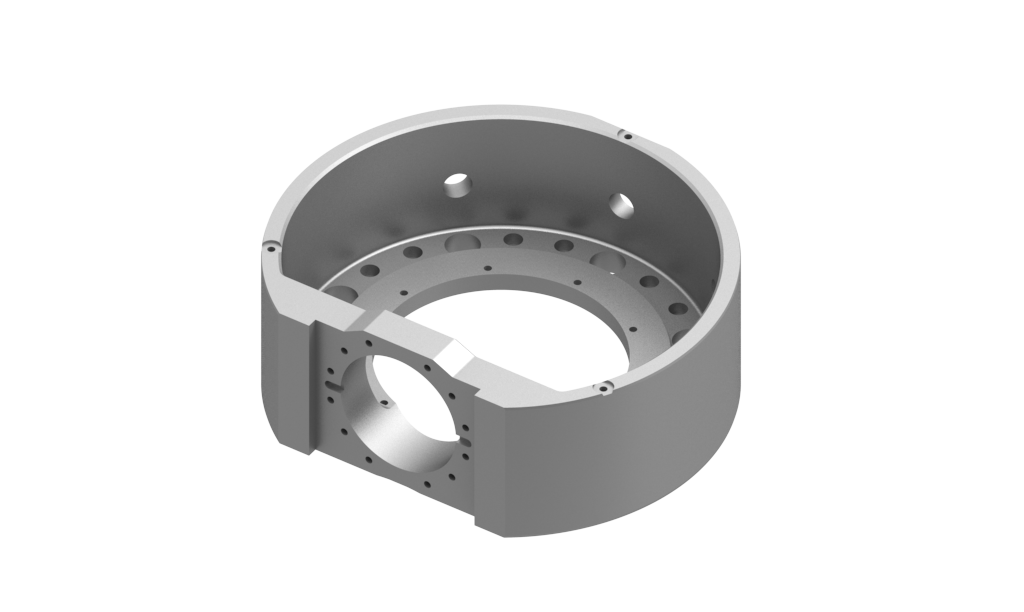

Precision sand casting is a specialized process, and at Ningbo Xingxin Industrial Co., Ltd., we offer cutting - edge precision sand casting solutions. Our approach combines traditional sand casting techniques with modern technological advancements to achieve outstanding results. We use high - quality sands and advanced molding methods to create molds with excellent dimensional stability. Our computer - controlled melting furnaces ensure precise metal pouring temperatures, reducing the risk of casting defects. After casting, our post - processing operations, including machining and surface finishing, are carried out with great precision to meet the exact requirements of our clients. In industries where large - scale production of parts with relatively simple geometries is required, but precision is still crucial, our precision sand casting solutions shine. For example, in the production of agricultural machinery components, construction equipment parts, and some automotive parts, our precision sand casting can provide cost - effective yet high - quality solutions. We work closely with clients to understand their specific needs, offering customized precision sand casting solutions that optimize both quality and production efficiency.