The Critical Role of Construction Machinery Castings in Heavy-Duty Applications

Defining Construction Machinery Castings and Their Core Functions

The castings used in construction machinery are basically what holds together excavators, bulldozers, and all sorts of heavy equipment. They're designed to take that brute force from engines and convert it into controlled movement across job sites. On actual mining operations or big infrastructure projects, these parts handle stresses well over 500 tons yet still keep everything aligned within about a quarter of a millimeter tolerance. A recent look at equipment performance in 2023 showed something interesting for quarry operators specifically. When they switched to better quality castings instead of relying on welded parts, breakdowns dropped by nearly 40%. That kind of reliability makes a huge difference when downtime costs money and safety is always a concern.

Superior Load-Bearing Capacity in Demanding Engineering Environments

Advanced casting designs distribute operational stresses across geometric profiles capable of withstanding 800+ MPa loads—equivalent to supporting nine fully loaded dump trucks on a single pivot point. This strength is essential in crawler crane slewing rings, where castings endure abrupt directional shifts while handling 2,500-ton lifting capacities without deformation.

Extended Operational Longevity Under Continuous Industrial Use

High-grade alloy formulations enable construction machinery castings to achieve 25,000+ service hours in port cargo handlers through three key innovations:

- Microstructure refinement increasing wear resistance by 55%

- Strategic ribbing patterns reducing thermal warpage

- Corrosion-resistant coatings lasting 8–10 years in marine environments

These advancements result in 29% lower lifetime maintenance costs for asphalt plants compared to traditional forged components, based on 2024 metallurgical analyses.

Precision Die Casting: Delivering Strength and Consistency in Construction Machinery Castings

How Precision Die Casting Enhances Structural Integrity of Construction Machinery Castings

In precision die casting, molten metal gets injected at high pressure into steel molds that can be reused many times over. This creates parts that are much denser with far fewer internal defects compared to what we see in older manufacturing techniques. The process allows for walls as thin as 1.5 millimeters yet still maintains a consistent grain structure throughout. This matters a lot when making things like hydraulic valves or boom attachments that have to handle repeated stress cycles day after day. Recent research from 2023 showed something interesting too: parts made through die casting actually lasted about 18 percent longer before showing signs of wear when tested under loads equivalent to 50 tons. That kind of durability makes all the difference in real world applications where equipment failure isn't an option.

High-Pressure vs. Gravity Die Casting: Choosing the Right Method for Durability

| Factor | High-Pressure Die Casting | Gravity Die Casting |

|---|---|---|

| Production Speed | 80—100 cycles/hour | 20—30 cycles/hour |

| Wall Thickness | 0.6—13 mm | 3—50 mm |

| Surface Roughness | Ra 1.6—3.2 µm | Ra 6.3—12.5 µm |

High-pressure die casting dominates production of complex, thin-walled components like gearbox housings, delivering 99.2% dimensional consistency across batches. Gravity casting remains ideal for thick-section parts such as counterweight cores, where controlled solidification prevents shrinkage defects.

Case Study: Performance Improvement in Excavator Components Using Advanced Die Casting

A leading OEM redesigned its excavator slew bearing housing using vacuum-assisted high-pressure die casting, reducing part weight by 23% while increasing maximum radial load capacity to 19,500 kgf. Near-net-shape accuracy eliminated 87% of post-casting machining operations, cutting production costs by $41 per unit.

Advancements in Dimensional Accuracy and Surface Finish for Industrial Reliability

When modern CNC machined dies work alongside real time thermal monitoring, they can hit positional tolerances around +/- 0.05 mm on those big 1 meter crane parts. The newer shot control systems have really cut down on surface porosity too, bringing it below 0.1% volume wise so we don't need any extra finishing before applying powder coat. Looking at what's happening in the field since 2022 through 2024, manufacturers are seeing about 40% fewer problems with early wear failures in those articulated loader joints. Makes sense when you think about how much better the materials hold up under stress now.

Advanced Materials: Aluminum and Magnesium Alloys in High-Performance Castings

Benefits of Lightweight Aluminum and Magnesium Alloys in Construction Machinery Castings

Aluminum and magnesium alloys are transforming construction machinery castings by combining strength with significant weight reductions. Components made from these materials are 34—45% lighter than steel equivalents while maintaining comparable load-bearing performance (Materials Engineering Journal 2023). Key benefits include:

- Enhanced maneuverability: Reduced mass improves response times in lifting and excavation tasks

- Structural resilience: High-pressure die-cast aluminum alloys like A380 withstand impact forces up to 750 MPa in bulldozer blade mounts

- Corrosion management: Magnesium alloys with proprietary coatings show 98% less pitting in saltwater environments compared to uncoated variants

Material Selection for Corrosion Resistance and Thermal Stability

Construction machinery castings require alloys designed for extreme conditions. Aluminum-silicon blends such as 356-T6 maintain dimensional stability at sustained temperatures up to 315°C, making them ideal for engine-adjacent components. Recent advances in magnesium-aluminum-zinc (AZ-series) alloys deliver:

- 9.2% slower corrosion progression in acidic soil environments versus standard carbon steels

- 18% faster heat dissipation in hydraulic system housings due to improved thermal conductivity

- Galvanic compatibility with steel fasteners through advanced surface treatments

Impact on Fuel Efficiency, Mobility, and Overall Machine Performance

The adoption of aluminum and magnesium alloys drives measurable gains across key operational metrics:

| Performance Factor | Aluminum Benefit | Magnesium Benefit |

|---|---|---|

| Fuel Consumption | 12—15% reduction in crawler cranes | 19% improvement in mobile crushers |

| Maintenance Intervals | 23% longer service cycles (excavator swing arms) | 31% reduced bearing wear (wheel loaders) |

| Worksite Mobility | 8% faster positioning in confined spaces | 14% higher payload capacity without structural compromise |

These material innovations allow manufacturers to meet emissions regulations while improving operational efficiency—a decisive advantage in competitive industrial markets.

Smart Foundry Innovations Transforming Construction Machinery Casting Production

Integration of automation and smart foundry systems for consistent quality

Today's foundries are getting much better at producing consistent castings for construction equipment thanks to all the automation they've added to their processes. The quality control systems powered by artificial intelligence can spot really tiny flaws that would otherwise go unnoticed, which means fewer defective parts end up being scrapped. According to a recent industry report from 2025, these smart systems cut down on waste by around 22 percent when compared to old fashioned visual checks. Foundries also use internet connected sensors to keep tabs on more than 140 different factors during production. This real time monitoring helps maintain just the right temperature when molten metal is poured and ensures proper cooling, resulting in stronger, more reliable castings that meet strict industry standards.

3D sand printing for complex, custom industrial components

Additive manufacturing is revolutionizing mold production. 3D sand printing enables intricate geometries—such as internal cooling channels in hydraulic castings—that conventional pattern-making cannot achieve, while cutting lead times by 40—60%.

Simulation and modeling software to reduce defects in castings

Digital twin technology predicts solidification behavior and stress concentrations during casting. Finite element analysis (FEA) optimizes wall thickness distribution, minimizing porosity in critical load-bearing joints and enhancing long-term reliability.

Balancing automation with skilled labor in modern foundry operations

Robotic systems now handle repetitive tasks like core setting and surface finishing, while experienced metallurgists focus on alloy development and process troubleshooting. This synergy increases overall equipment effectiveness (OEE) by 18% in advanced facilities.

Future trends in digitalization and sustainable manufacturing for metal castings

The industry is adopting closed-loop systems that recycle 92% of sand mold materials. Blockchain-based traceability ensures responsible sourcing of raw metals, and hydrogen-fueled melting furnaces demonstrate potential to cut CO₂ emissions by 65% compared to coke-fired units.

Custom Industrial Components: Meeting OEM Demands in Specialized Construction Applications

Tailoring Construction Machinery Castings for Specific Equipment Types

Construction today calls for cast parts made specifically for how machines actually work on site. Take bulldozers for instance their track frames need serious torsional strength to handle rough terrain without twisting apart. Crane turntables are different they must have those exact gear interfaces so everything rotates smoothly when lifting heavy loads. Foundries tackle this challenge in several ways. They tweak the metal mixtures, change how thick the walls are, and adjust where reinforcements go based on what each piece of equipment requires. A good case study comes from vibratory rollers. These machines rely on components made from nickel alloyed ductile iron because regular materials just cant stand up to the constant pressure cycles these parts face, sometimes over 60 MPa according to recent industry findings.

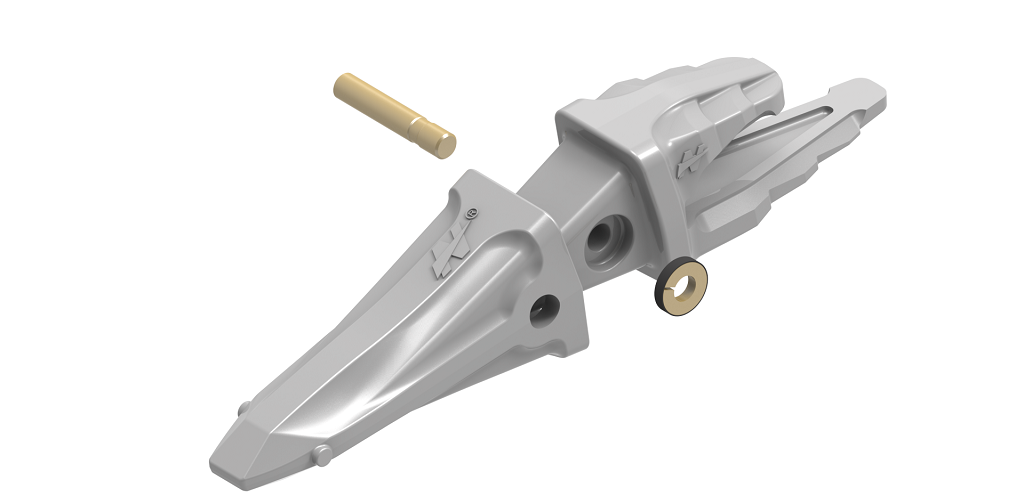

Precision-Engineered Castings to Meet Strict OEM Specifications

Most original equipment manufacturers insist on keeping dimensional tolerances tight around ±0.2 mm when it comes to those important load bearing components found in things like excavator pivot joints. For checking what's going on inside these parts, advanced CT scanning has become standard practice. Meanwhile robotic grinding systems can get surface finishes down under 3.2 microns Ra which makes all the difference when these parts need to work smoothly with hydraulic systems pushing over 350 bar pressure. The latest modular mold designs are changing the game too. They make it possible to produce smaller batches of custom castings at reasonable costs. This is particularly useful for making prototypes of specialized mining shovels or parts needed for tunnel boring machines where quantity isn't always the main concern.

FAQ Section

What are construction machinery castings?

Construction machinery castings are critical components used in heavy equipment such as excavators and bulldozers. They convert engine force into controlled movement, ensuring equipment reliability and precise operation.

How do advanced casting designs enhance load-bearing capacity?

Advanced casting designs distribute operational stresses across geometric profiles, enabling them to withstand loads of 800+ MPa and support heavy machinery operations without deformation.

What are the benefits of using aluminum and magnesium alloys?

Using aluminum and magnesium alloys in construction machinery castings offers significant weight reductions, enhanced maneuverability, structural resilience, and improved corrosion management.

How do smart foundry innovations improve casting quality?

Smart foundry innovations use automation, AI-powered quality control, and real-time monitoring to produce stronger, more reliable castings that meet strict industry standards.

Table of Contents

- The Critical Role of Construction Machinery Castings in Heavy-Duty Applications

-

Precision Die Casting: Delivering Strength and Consistency in Construction Machinery Castings

- How Precision Die Casting Enhances Structural Integrity of Construction Machinery Castings

- High-Pressure vs. Gravity Die Casting: Choosing the Right Method for Durability

- Case Study: Performance Improvement in Excavator Components Using Advanced Die Casting

- Advancements in Dimensional Accuracy and Surface Finish for Industrial Reliability

- Advanced Materials: Aluminum and Magnesium Alloys in High-Performance Castings

-

Smart Foundry Innovations Transforming Construction Machinery Casting Production

- Integration of automation and smart foundry systems for consistent quality

- 3D sand printing for complex, custom industrial components

- Simulation and modeling software to reduce defects in castings

- Balancing automation with skilled labor in modern foundry operations

- Future trends in digitalization and sustainable manufacturing for metal castings

- Custom Industrial Components: Meeting OEM Demands in Specialized Construction Applications

- FAQ Section